Every once in a while I need to draft a pattern for (and sew) something that is not a quilt. Right now I am finishing up making fitted cushion covers for some mattresses in our tiny travel trailer. Why would I do such a thing? It needs doing and there are no commercially available covers in the right size. So unless I want to pay an upholsterer to do the job – I’m doing it myself.

The funny thing is – I’m right back to doing the very first sewing project I ever undertook as a 10 year old kid. As a child – the person who used the sewing machine in our house was my grandfather. He had some amazing skills – and expected me to learn as well.

The first project we tackled was creating new covers for the cushions on the furniture on the front porch. We started by drafting the patterns. I learned about ease, seam allowance, and matching the type and weight of thread I used with the fabric for the project. Then I learned how to make my own piping and insert it into the seam between the pieces for the cushion cover. Sewing things inside out (in the right order) and having them fit correctly when turned right side out was another new skill I learned from him.

Here I am all these years later – doing exactly the same kind of project. I’ve been hearing his voice in my head with every piece I cut and every stitch I take.

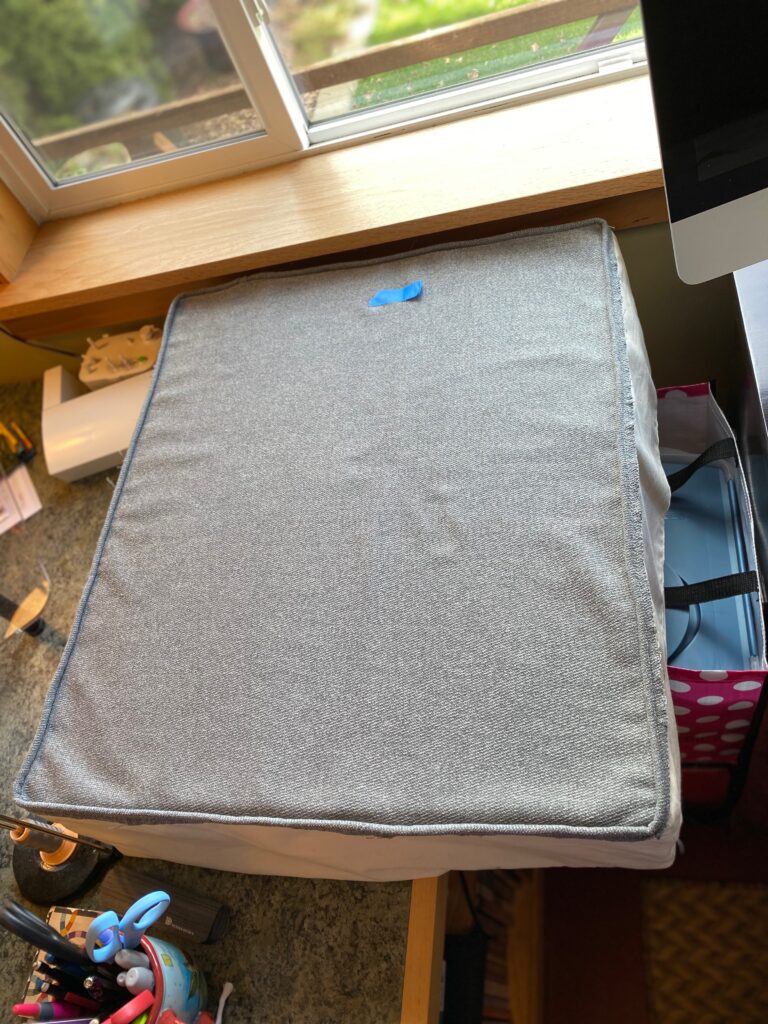

The cushion is a 6-inch deep memory foam/gel foam mattress that we cut down to the right sizes for our trailer. As you can see in the picture below (showing one of the mattresses) – each mattress is cut into 2 pieces (one long and one roughly square). Doing it this way means that we can easily move the smaller portion to get to the storage area underneath. These newly covered mattresses with fitted cushion covers are replacing the thin, vinyl-covered cushions that came with the trailer (good riddance!)

Not going to lie – this can be a challenging project but so worth it when it’s all done. I used a polyester upholstery fabric in a medium weight, matching poly thread, and sew-in velcro for the end with the opening.

Tips:

- It’s all in the foot: Use a piping foot for your machine – whether you make your own piping or use commercially made piping – it makes all the difference in accuracy.

- Thread: Use poly thread if you are using poly fabric. Cotton thread is no match for the poly fabric and will fail over time.

- Mark the right side of every piece of fabric that you cut. The fabric I used was almost exactly the same on the front and back sides. Almost. Getting it wrong will drive you crazy – if you don’t notice it until after the cover is complete.

- Directional Fabrics: If you are using directional fabrics – be very careful in making your cutting plan to ensure you have calculated (and purchased) enough fabric for your project.

- Quilting clips: these clips are your best friends. Most upholstery fabrics are too heavy for pins to work effectively – these clips secure all the edges in place without distorting the fabric.